Global, Health, Research

Reinventing the Toilet

Reinventing the Toilet: Seeking a ‘Safe and Dignified Solution’ to the Sanitation Crisis

by Ken Kingery

Duke University has become a hub of research to improve the way the world protects people and water from human waste. A recipient of multiple grants from the Bill & Melinda Gates Foundation, the Center for WaSH-AID and two emerging technologies hope to reshape the lives and health of billions of people both worldwide and at home.

“The opportunities to learn through having toilets in the field are just amazing.”

-Brian Stoner

We all know that everyone poops. But no one should have to live with the results.

Unfortunately, the reality today is that about 1 billion people defecate openly and 2.4 billion are using unsafe sanitation that allows human waste to mix with water sources used for cleaning and drinking.

While many live in rapidly growing urban areas where household and communal toilets are more prevalent, pit latrines and connections to septic tanks are often not safely maintained and raw sewage is simply discharged into open drains or surface waters.

The consequences are staggering. Just one, the World Health Organization estimates, is that 525,000 children under the age of five die each year from diarrheal illnesses linked to poor sanitation.

But with clever ideas and a lot of hard work, help is on the way. Duke is home to two of the “Reinvent The Toilet” efforts funded by the Bill & Melinda Gates Foundation to address this massive problem.

The concentration of expertise here has also led to the development of a national Sanitation Technology Cluster based at Duke.

Through the Duke University Center for WaSH-AID (Water, Sanitation, Hygiene and Infectious Disease), director and Duke Engineering research professor Brian R. Stoner oversees an entire portfolio of promising sanitation technologies being developed by research teams all over the United States. Their work will go beyond toilet designs to create and commercialize technologies that improve access to clean water, sanitation and hygiene, sometimes called WASH.

When Flushing Isn't Enough

Even as he was attending a two-day symposium intended to attract scientific talent to address sanitation, Stoner knew his idea could work.

The keynote address of the 2012 meeting was delivered by Doulaye Kone, Ph.D., an experienced water specialist who had just been hired by the Gates Foundation to lead a then-fledgling program called the Reinvent the Toilet Challenge.

Although only a year old at the time, the program already had a lot of irons in the fire, having invested a total of $3.2 million in eight innovative sanitation projects. Kone was on the hunt for even more ideas to support and, after speaking with Stoner over the course of the next few days, invited him to submit a proposal.

The timing was great. Stoner, now a research professor of electrical and computer engineering at Duke, had spent the past several years at RTI International in North Carolina’s Research Triangle pursuing the broad charge of breaking down silos to create better materials for global health technologies.

The Duke research has evolved into a full-scale beta prototype system which was installed in early 2018 at a women’s textile mill dormitory in Coimbatore, India.

“I spent my earlier career as a materials scientist, developing novel materials that others would use to improve liquid waste,” said Stoner.

With two promising technological solutions to the toilet problem already in mind, Stoner and his colleagues at RTI International and Duke University put together a proposal for the Gates Foundation in less than 48 hours.

One of those ideas was called electrochemical treatment -- using electricity to create sanitizing chemicals like chlorine from the waste itself.

His father, University of Virginia professor emeritus Glenn Stoner, had led much of the breakthrough research in the electrochemical treatment of sewage for the US Navy in the early 1970s. Pivoting to the subject of sanitation later in his own career felt like coming home.

“At RTI, some collaborators worked on creating cleaner cooking stoves for the developing world and we discussed how to leverage this knowledge to create a cleaner-burning system for treating human solid waste,” Stoner said. “And through my father’s work, I knew it was possible to electrochemically treat liquid waste to a point sufficient to discharge it in an environmentally friendly matter. We put these two concepts together and formed the basis of our first Reinvent the Toilet research proposal.”

As it turned out, Stoner’s father would provide more than inspiration for the proposal. Jeff Glass, one of Glenn Stoner’s former doctoral students, also happened to be a professor of electrical and computer engineering at Duke. A friend and longtime collaborator, Glass was a perfect partner for the project.

Stoner and Glass proposed burning dried human waste to generate heat that could be converted to electricity by thermoelectric materials. That electricity would then power an electrochemical reaction through a new material -- boron-doped diamond coatings – generating the disinfectants needed to sanitize the system’s fluids.

The Gates Foundation awarded the idea $1.5 million, giving Stoner and Glass one of the dozen initial projects funded through the Reinvent the Toilet Challenge.

Soon after, another Duke colleague entered the picture with a different technological approach. Marc Deshusses, a professor of civil and environmental engineering, pitched the idea of fitting a supercritical water oxidation system—or as Deshusses calls it, a “pressure cooker on steroids”—into a standard 20-foot shipping container to turn human waste into clean water, carbon dioxide and energy in mere seconds.

The Gates Foundation again said yes.

Both Duke ideas showed promising results and have now entered into advanced testing, with both next-generation units garnering slots at a special invitation-only Reinvented Toilet Exposition hosted by the Gates Foundation in Beijing this November.

Marc Deshusses created a system that uses enormous pressure and high heat to burn sewage into harmless byproducts.

No One Solution Would Work

“None of these projects are going to result in a silver bullet that solves the problem globally,” Glass said while showing off several of the projects the groups is overseeing at its brand-new research space in The Chesterfield Building. A renovated cigarette factory in downtown Durham, North Carolina, The Chesterfield is Duke’s latest innovation hub where faculty and students from several departments rub elbows with private startups.

“Each solution is just a piece of the larger puzzle. One project might develop a component that proves to be a key ingredient in overcoming another’s problem,” Glass continued. “One design might work well for rural African cultures while another is better suited for urban settings in India. But because there’s so much research being done under the Gates Foundation umbrella, there are more opportunities to find the custom solutions that work.”

It’s both an engineering problem and a matter of understanding culture and attitudes. A potential solution can’t work only in ideal conditions on a university’s campus as a one-off prototype. The systems have to be robust enough to face the unpredictable wear and tear of daily use while remaining economically viable and appropriate to the infrastructure of their sites.

That’s why the Reinvent the Toilet Challenge rules are so stringent. For systems to be considered successful, they must not only remove pathogens from human waste and recover resources such as energy, clean water and nutrients, they have to do this “off the grid,” without access to external electricity or water sources. Oh, and the toilet must cost less than five cents per user, per day -- that’s 200 users for ten bucks.

Those are engineering problems. Now add the human factors. Most cultures are wary of newcomers telling them what to do in the best of circumstances -- and become doubly so when dealing with one of the most private moments of daily life. Different parts of the world also eat different diets and have different ways of cleaning themselves after using the toilet.

Even when you address all of those concerns, people still have to choose to use the system. People stopped using the first prototype of the Stoner/Glass design at a site in India because the treated water being reused for flushing looked "dirty" in the bowl. While it met the necessary sanitation requirements, the researchers had to find a way to make it look clean before people would use the toilet.

The Trouble-Shooting Never Ends

Both of Duke’s Reinvent the Toilet Challenge projects have faced their share of obstacles over the years, some easier to anticipate than others.

For Deshusses’s high-pressure, high-temperature machine, the challenge has been solving engineering problems where others have already failed. The system relies on technology called supercritical water oxidation, or SCWO for short.

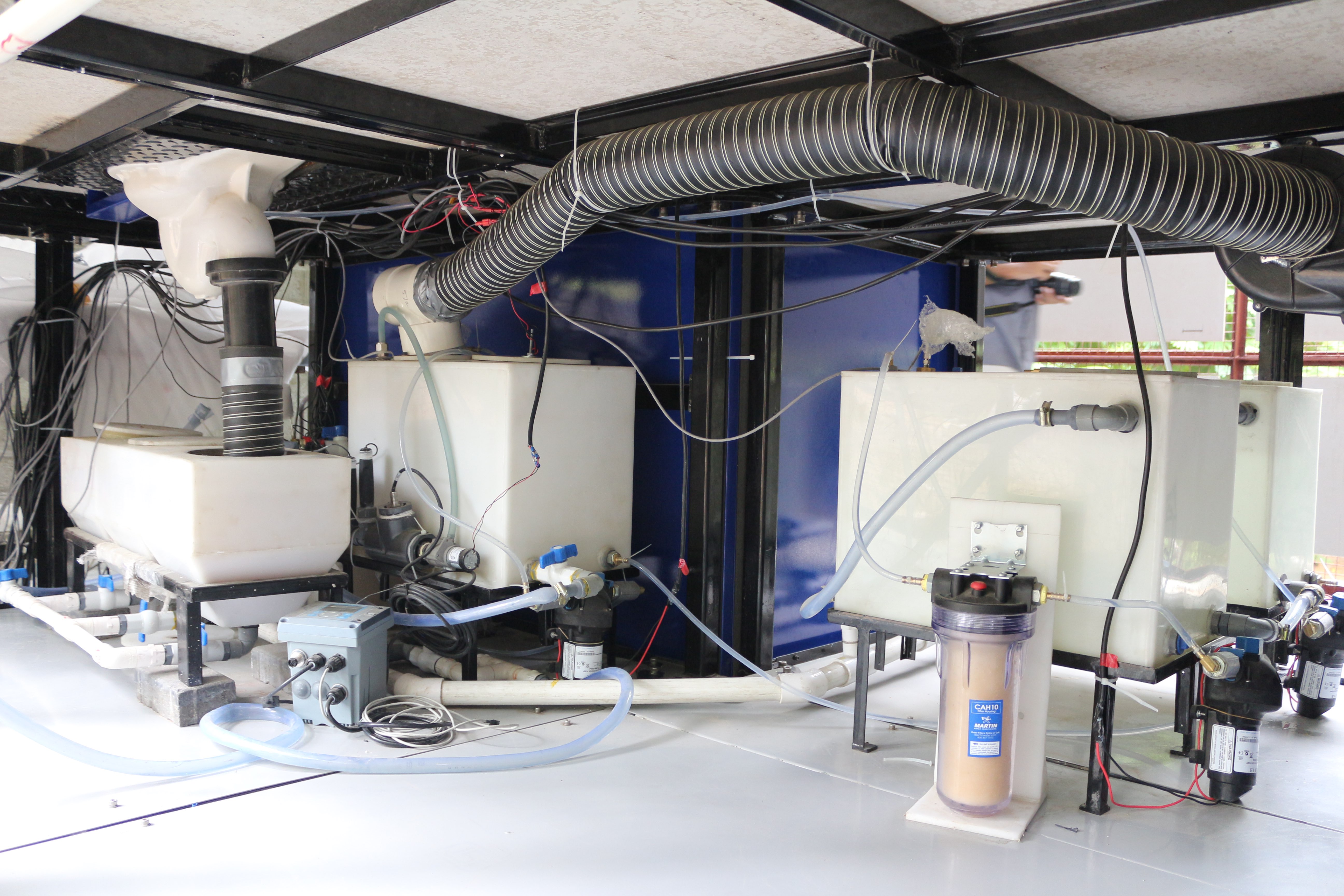

A glimpse at the technology below the bowl (at left) in one of the prototype systems.

Marc Deshusses explains the challenges of his work in a 2017 video.

SCWO relies on the unique properties of water or slurries brought above the critical point 705 degrees Fahrenheit and 3200 pounds per square inch. Under these conditions, any organic waste -- including human waste -- is quickly converted in a single stage to clean water, carbon dioxide, non-leachable inorganic salts and energy.

“At these conditions, the organic matter in the fecal waste burns extremely fast,” said Deshusses. “In something like four seconds, we go from fecal waste to carbon dioxide and water.”

The real proof in the pudding, however, is the results. All pathogens and micro-pollutants are destroyed without any sort of chemicals or catalysts needed. And depending on the energy content of the waste being treated, the SCWO units can work off-grid and even generate a surplus of electricity.

SCWO has already proven its worth by destroying hazardous wastes such as polychlorinated biphenyls (PCBs) and chemical weapons. When treating human waste, the reaction produces clean water, heat, carbon dioxide, benign salts and nitrogen, which can be used by the community or turned into business opportunities that support the system. For example, the water could be used in community showers or clothes-washing facilities and the salts and nitrogen could be used as fertilizer.

Deshusses’s team has worked for years to build a pilot system on Duke’s campus large enough to serve an entire small community in a 20-foot blue container. Looking something like a boxcar behind the Hudson Engineering Building, it is efficient enough to run off of little more than solar panels, and capable of producing water clean enough for people to be willing to reuse it.

“Being at a university has given us the ability to learn from others’ mistakes, innovate quickly and address problems early on,” said Kobe Nagar, the SCWO team principal engineer. “Our prototype has proven successful thanks to a unique reactor configuration that reduces the energy demand to sustainable levels.”

The key step has been properly preheating the incoming stream of waste with the heat of the ongoing reaction. Once the system gets to the operation temperature, the energy embedded in the waste is enough to sustain the reaction and keep the unit running continuously.

There remain, however, more challenges to overcome than simply getting the technology to work.

Technical Solutions Face Reality

The toilet project Stoner leads has also faced many technical challenges. The original pitch to the Gates Foundation that separated, dried, and burned solid waste to spark a sanitizing chemical reaction faced major hurdles right from the start.

The project’s ace in the hole was Glass’s research team, which had expertise in electrochemistry. In this case, electricity would be run through mostly liquid human waste, which contains a decent amount of salts. The electricity breaks down the molecular bonds within these salts, producing chlorine-containing oxidants, a powerful disinfectant.

Even though Glass had more research experience with fuel cells -- devices that split water to generate hydrogen for fuel -- his knowledge could easily translate to the sanitation task at hand.

“Electrochemically treating hazardous waste has a lot of benefits,” said Glass. “You don’t have to ship or handle any chemicals for the disinfection, and the process can be very efficient.”

In their earlier research Glass and Stoner worked together developing a particularly efficient material for the project’s needs called boron-doped diamond. A synthetically grown diamond, this material creates a lot of oxidants without wasting its energy on splitting water into gaseous forms of hydrogen and oxygen. This efficiency is critical because pathogens have to be in contact with the oxidants for a certain amount of time to be destroyed, and oxidants don’t last forever.

There’s just one catch – boron-doped diamond is almost as expensive as the name would imply. Fortunately, there are technologies that work almost as well for only about five percent of the cost.

This schematic animation illustrates the principles behind the “Empower Sanitation Platform.”

Rather than trying to push through with the costly diamond, the team opted for a much cheaper solution involving a set of filters, including charcoal. This approach first removes most of the solid contaminants, which consume much of the available oxidants. The hazards remaining in the liquid could then be electrochemically treated with a less efficient -- but much cheaper -- alternative.

"Pivoting away from the boron-doped diamond is part of what makes this project a rarity on a university campus,” said Glass. “Rather than running experiments to find the best material for a job -- no matter the cost -- we found a solution that wasn’t quite as good, but good enough and much cheaper. That’s the difference between basic research and product development.”

Stoner’s idea to generate energy from burning the dried waste suffered a similar fate. While a good idea at face value, the thermoelectric materials they needed have not become as efficient or inexpensive over the past several years as Stoner had hoped. Rather than spending months trying to figure out a way around these issues, Stoner and Glass decided to ditch that part of the design as well.

So while the solids are still burned to reduce the final volume of waste, they are no longer being used to generate electricity. For the small amount of power needed to support the electrochemical disinfection, the system instead relies on more traditional sources such as solar power.

The Social Side of Toilets

For Stoner, Glass and their team members, the social challenges have been at least as difficult to overcome as the technical ones. Their two test systems in India and one in South Africa have taught them a lot.

“In these communities, it’s common for people to carry a bucket of water to the toilet because automatic flushing doesn’t exist in many low-income communities,” Stoner said. “So instead of pushing the button to flush, they’d just pour water into the toilet. And because the button to flush wasn’t getting pushed, the system wouldn’t realize what was happening and it would overflow the processing unit.”

“After months of confusion, we also discovered our prototypes were wearing down too quickly thanks to some good intentions,” Stoner said. “It turned out that before every major visit we made to our site, the locals and operators would dump a whole bottle of cleaning solution down the toilet. They just wanted to make the unit smell better, but they were corroding the components. So every time we had important visitors, the system wouldn’t work. The opportunities to learn through having toilets in the field are just amazing.”

Now-comical anecdotes aside, Stoner and Glass have been working hard to understand these societal complications. The team began recognizing site-specific constraints and needs through their early field trials and a parallel study aimed at better understanding each user community -- particularly women.

“Westerners typically think of the toilet as a gender-neutral thing, but in reality the requirements vary tremendously by gender,” Stoner said, pointing out that women in poor and developing areas are disproportionately disadvantaged by a lack of sanitation than men. “If our goal is to provide a safe and dignified solution, we need to address that asymmetry.”

Whereas it is often not taboo for men to practice open defecation, women may have to go to the toilet by the cover of night or early morning. Lighting, safety and security thus all became concerns during the engineering process.

In some parts of India, millions of girls drop out of school once they hit puberty because of a lack of facilities for menstrual hygiene. As the team learned more about these challenges, they realized that matriarchs were often the gatekeepers to the entire village’s adoption of new ideas. Unless the older women adopted the new technology, nobody would.

“So while we’re thinking of engineering solutions, our ideas are always tinted by the social implications,” said Stoner. “We have to address those needs as well, or we’re not going to be successful.”

Spinning It All Out

Stoner and Glass’s first full-scale beta prototype was installed early in 2018 at a women’s dormitory at a textile mill in Coimbatore, India. A second was up and running only a few months later in a township outside of Durban, South Africa.

Before these two systems could be built, an initial prototype had been installed at the CEPT University in Ahmedabad, India. Though critical for gaining early insights, it had its limitations, as the researchers could control how much the system was used and take it offline anytime they needed to. The installations in Coimbatore and South Africa are a significant step forward because they will spend the next year in full operation in a real-life setting.

"Success in a laboratory setting is an important first step, but testing it in more realistic conditions will help show where we can still make improvements,” Stoner said. “These installations will really put the sanitation system through its paces.”

"This is an important year for us," Glass said. "Besides proving that our sanitation system can work and that people will use it, we're also hoping to partner with potential manufacturers who want to translate the prototypes into a commercial product."

At the November 2018 Reinvented Toilet Exposition in Beijing, Stoner and Glass will be searching for potential commercial partners to pitch.

At home, the project has already found some initial commercial partners. A Connecticut-based business focusing on thermal fecal sludge management called Biomass Controls has opened a small facility in downtown Durham to help transition the technology into the field trials.

"Our goal is not to manufacture these systems ourselves," Stoner said. "Instead we want to be a catalyst for commercialization, by creating a collaborative environment between researchers and product development partners focused on launching innovative, sustainable solutions."

Deshusses’s SCWO technology is on a similar path, now actively pursuing private partners for commercialization.

Top: The facilities in a women’s dormitory at the textile mill in Coimbatore, South Africa, where a Duke prototype has been installed.

After running the system for the past three years and testing operation with various feedstocks -- from wastewater treatment plant residues called biosolids to dog poop -- the project passed an important milestone Gates Foundation review in late 2017. The shipping-container-sized project received a third round of funding to begin its own commercialization forming a spinoff company called 374Water.

With many lessons in hand from the low-capacity testing bed on Duke’s campus, Deshusses now aims to have one full-scale commercial demo system operating in the United States and a second in a developing country to show that they are ready for mass production by 2020.

“Sometimes you just need to leap and the industry will follow,” said Nagar.

These demonstration systems will have two major upgrades from the current pilot. An “expander” will generate energy with a high-speed turbine powered by the heat and gas coming off the supercritical oxidation process. And the system is being scaled up so that it can accommodate a community of up to 6,000 people, the point at which the system becomes energetically self-sufficient and less expensive to run.

“The technology is there. The challenge is really in engineering a system that can do it reliably and economically,” Deshusses said. “The potential of supercritical water oxidation is enormous, because you can build units that are very compact and embed them in communities, or you can build large units that can treat the waste of small cities and turn any type of organic waste into clean water.”

Think Globally, Treat Locally

With the WaSH Sanitary Technology Cluster, two toilet projects and evident entrepreneurial zeal, Duke and Durham are becoming a major hub that supports the Gates Foundation’s sanitation initiative.

“The Gates Foundation has funded a portfolio of parallel technology development programs that all address different gaps and needs,” Glass said. “By consolidating them into a single cluster, we can identify partners to help all these different projects in their development process.”

One example is a liquid treatment module that was developed under the technology cluster and recently manufacture by Mountain Safety Research (MSR) for the Reinvented Toilet Exposition in Beijing, a great example of industry partners working with university research groups to transition technologies from lab to products.

“The real value of this clustered approach is that we can encourage and manage partnerships and develop cross-cutting insights,” said Stoner. “We’re going to adopt a ‘fail early, fail fast’ culture.”

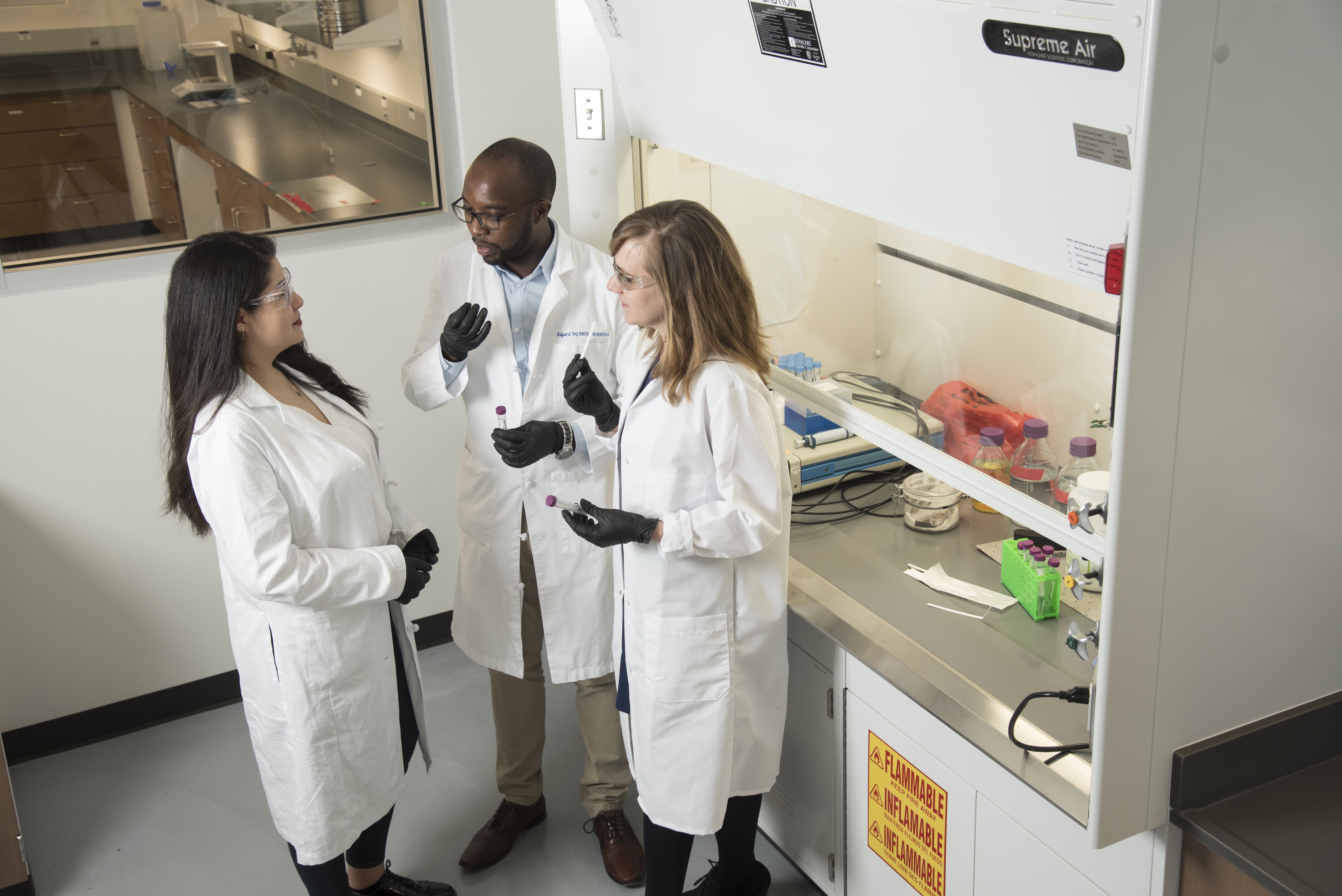

The Center for WaSH-AID has spent the past year hiring a flock of talented researchers to help shepherd a number of projects through the Gates Foundation development process.

Since most of these ideas are aimed at providing 2.5 billion people in the developing world with basic sanitation, it can be easy to forget that sanitation systems in developed nations are far from perfect themselves. Stoner, Glass and Deshusses all believe their projects could and should have an eventual impact right here in the United States, and even envision a future with an “Internet of Toilets,” which was coined by Krishnendu Chakrabarty, chair of Duke’s Department of Electrical and Computer Engineering.

Many sewer systems in major cities are aging rapidly, and updating them will be a gigantic and expensive undertaking. Instead, the Duke researchers argue that we might consider turning to smaller, decentralized systems such as these that could serve individual communities and even homes without requiring a sewage hook-up.

“Our first goal is to address rural, low-resource populations that don’t have any infrastructure at all,” Glass said. “But then I can envision moving toward more populated areas like retirement homes or military bases and converting them to decentralized systems. This is not right-around-the-corner by any means, but I have no doubt that this technology would be valuable for regions right here in the United States, especially in places that already have weak septic systems or waste management facilities.”

Even with robust sewage treatment systems, there are always improvements to make. For example, the treatment plant for New York City handles 36,000 tons of wet sewage from various sources each month, and more than a quarter of it ends up in landfills. If a few scaled-up versions of Deshusses’s supercritical oxidation system could be parked nearby, they could theoretically reduce the amount of excess solids by more than 97 percent.

With the growth of confined animal feeding operations (CAFO), like the massive hog, chicken and turkey farms of North Carolina, these solutions might be applied to more than human waste.

The historical rains of Hurricane Florence in North Carolina recently made it very clear that waste management on hog farms could use some improvement. Rather than giant lagoons susceptible to flooding and overflowing, decentralized treatment facilities could provide a better, cleaner option that would be much more resilient to storms.

According to Deshusses, his supercritical water oxidation system does not need any modifications to treat animal wastes. The machinery is also much smaller than lagoons, thus freeing up space for cash crops or more barns for animals.

“The added benefit is that we will eliminate all antibiotic resistant bacteria, all the nuisances such as odors and flies, and many more of the issues caused by current lagoons,” Deshusses said.

Today, where there is technology, there is data. Glass envisions smarter sanitation systems also being a source of knowledge. “Human waste is an incredible repository of health information,” Glass said.

For example, a startup company called Biobot Analytics is partnering with the town of Cary, North Carolina to measure the concentration of opioids in sewage to estimate levels of drug use. Similar methods could be used to track or even predict outbreaks of viral or bacterial infections.

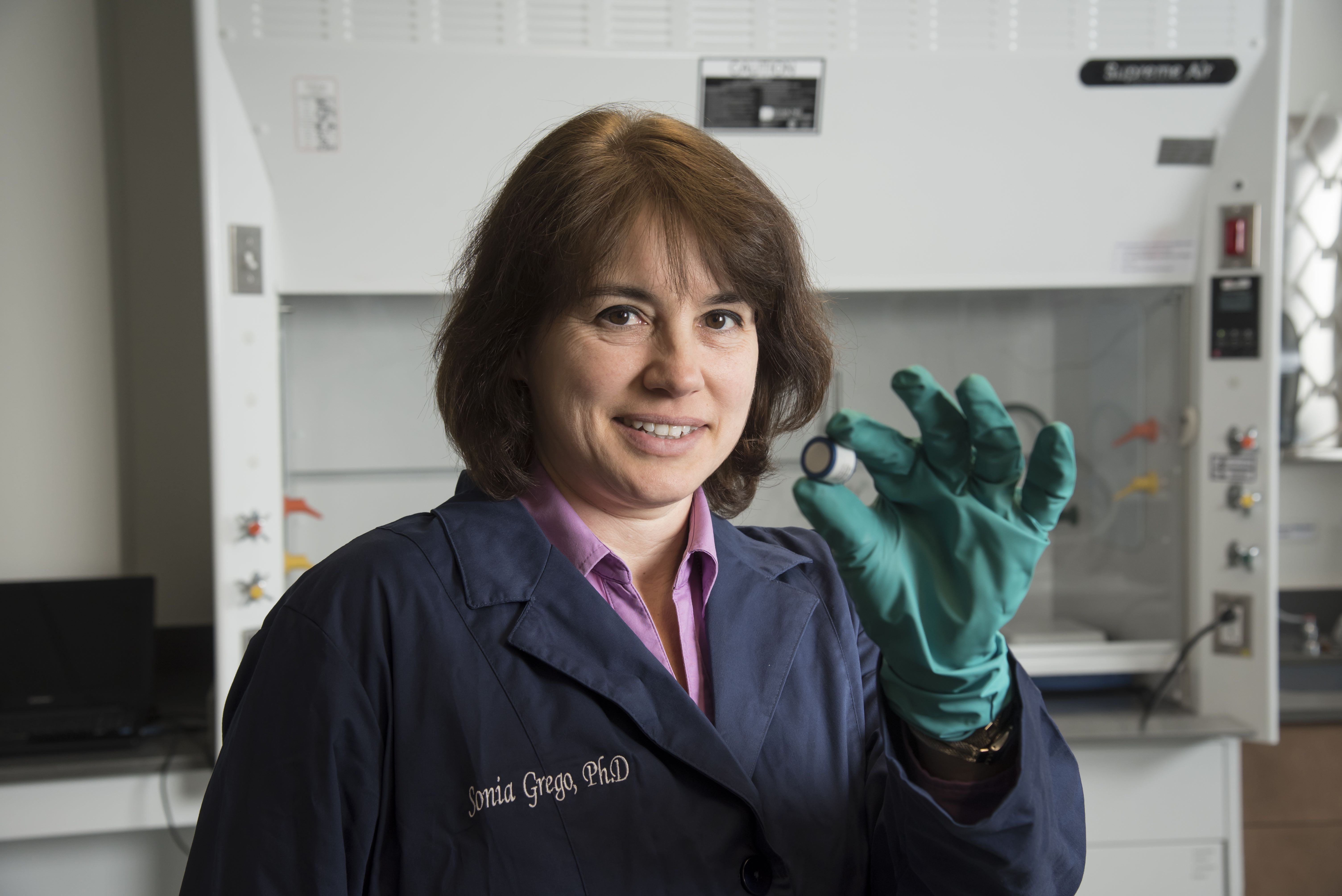

Taking this idea another step further, Glass and Stoner, collaborating with Geoff Ginsburg of the Duke University School of Medicine and Sonia Grego in the WaSH-AID Center, imagine a new type of “smart toilet” that could monitor the health of individual households.

“Nobody wants to collect their own feces unless it’s absolutely necessary,” he added. “If we could automate that and do in-line sensing for urine and feces, that information could be sent to a centralized data analytics resource. And with today’s unprecedented computing power, we could understand trends and correlations across populations. Not only could we help predict illness in individuals, we could potentially stop epidemics before they start.”

For World Toilet Day in 2017, the two projects joined forces to celebrate all of the sanitation milestones achieved at Duke University. These included the creation of full-scale prototype systems, the establishment of the Center for WaSH-AID, and the achievement of several technological benchmarks needed to make the technologies successful.

Story by Ken Kingery, Pratt School of Engineering

Produced by University Communications